Cassava starch production line

Date:

Date:

June 19, 2019

- WhatsApp:

- Tel:

- Phone:

- Email:

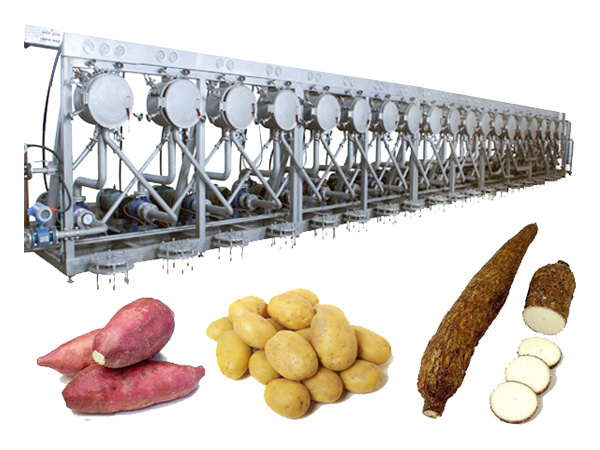

As we all know, for the starch business the most concerned how to extract starch from cassava tubers, potatoes, sweet potatoes in high starch extraction rate. Cassava is a surface rough plants. The vast majority of dry cassava starch, fresh cassava tubers starch containing about 25% -30%, in the dry matter contains about 80%. Our task is to extract the starch refinery we need from starch tubers.

Cassava starch processing principle: The cassava starch production process is a physical separation process, which separates the starch in the cassava raw material from cellulose, protein, inorganic substances and the like. In the production process, the root starch is insoluble in cold water and the specific gravity is greater than water. Water and special mechanical equipment are used to separate the starch from the water suspension to achieve the purpose of extracting starch.

Cassava starch production line main machines

Cassava starch production line main machines

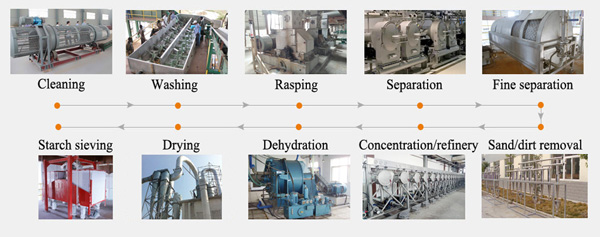

Cassava starch processing process: Doing Company manufactured cassava starch production line adopts the wet processing technology of starch production without adding any additives. The whole process is mature in technology, advanced in equipment, scientific in configuration and reasonable in process. The cassava starch production process is designed according to the six sections of cleaning→crushing→separation→concentration and refining→dehydration→drying. In particular, the crushing section is completed by a high-efficiency rasper machine, which has the advantages of low energy consumption, high starch extraction rate and good starch quality, and improves the production efficiency of the production line and the extraction rate of starch, so that the extraction rate of cassava starch exceeds 94%.

The starch processing factory overview

The starch processing factory overview

Below is the cassava starch production line each processing section introduction:

1. Cassava cleaning and washing section for cassava starch production line:The purpose of this unit is to get rid of sandstone, clay of cassava, and to deposit cleaned cassava in the cassava temporary hopper.

2. Crushing section during the cassava starch production line: The crushing unit is the most important step for extracting cassava starch. Highly-efficient crushing machine will release the starch in cassava at most.

Rasper machine details

Rasper machine details

3. Centrifugal extracting section during the cassava starch production line:The cassava starch slurry and residue will be separated from the starch milk.

4. Desanding section during the cassava starch production line: Removing the sand in the starch slurry.

Centrifuge sieve in cassava starch plant

Centrifuge sieve in cassava starch plant

5. Concentration and refining section during the cassava starch production line:Working through the hydroclone, there are 2 steps, including concentration and refining so that we can get purier starch slurry.

6. Sarch milk dewatering section during the cassava starch production line: The starch milk is pumped into inlet tank of peeler centrifuge machine. The peeler centrifuge now is the most suitable machine for cassava starch dewatering, after this process, we can get the wet cassava starch with moisture about 36.5%. Then can be send to the drying process.

Peeler centrifuge

Peeler centrifuge

7. Air-stream drying section during the cassava starch production line: After dewatering process, the air dryer will dry the starch to the required moisture of the commercial starch.

Above all steps are the whole line for cassava starch production.We can provide you the complete cassava starch production machine and we have exported many sets cassava starch processing machine to Nigeria and other Africa countries.

Produced starch

Produced starch

Applicable objects and features of DOING modern cassava starch production line:

Doing Company's cassava starch production machines is suitable for medium and above-scale starch processing manufacturers and customers who use cassava as raw material. The process is fully automated from the whole process of cleaning, crushing, starch extraction, fine separation, sand removal, concentration, refining, dehydration and drying. The machine's processing volume is large, the production cycle is short, and the raw materials only need more than ten minutes from cleaning to finished products, effectively avoiding the long-term exposure of the starch slurry to the air, oxidative browning, secondary pollution of dust and microorganisms, and improving product production efficiency and finished cassava starch quality.

Following is Doing Company supplied cassava starch production line main machines configuration:

| NO. | Name | Function |

| 1 | Hopper+Belt scraper conveyor | Temporary storage, lifting and transporting of cassava |

| 2 | Dry sieve | Remove dirt, sand, small stones, weeds,etc. on the cassava surface |

| 3 | Paddle washer | Further washing, remove sediment and other impurities |

| 4 | Belt scraper conveyor | Lift, transport, pick |

| 5 | Rasper | Crushing cassava to free starch |

| 6 | Centrifuge sieve | Separate the fiber and starch slurry |

| 7 | Fine fiber sieve | Further separating fine fiber from starch slurry |

| 8 | Desander | Remove residual sediment |

| 9 | Disc separator | Protein removal, concentrated starch slurry |

| 10 | Hydrocyclone station | Concentration&refinery |

| 11 | Peeler centrifuge | Dehydrate starch milk to below 38% |

| 12 | Belt converoy | Delivery wet starch |

| 13 | Flash dryer | Starch dried to qualified(12%-18%) |

| 14 | Starch sieving machine | Dry starch sieving |

| 15 | Packing machine | Automatic packing |

The cassava starch production line auxiliary facilities:

Boilers, transformers and power distribution cabinets, water supply systems, corresponding warehouses and stacking sites, tiny granular starch collection tanks, transfer tanks, etc.

Leave a message about Cassava starch production line

- Do you want to buy machine?

- Yes, I want to buy machine

- No, I want to learn more in advance.

- What is your raw material?

- Cassava

- Potato

- Sweet potato

- Others

- 2. What is the final product you want to produce?

- Garri

- Cassava flour

- Cassava starch

- Cassava chips

- Attiekie

- Bammy

- Others

- 3.What is your capacity plan?

- Small scale garri machine

- 1ton per day

- 2tons per day

- 3tons per day

- 10tons per day

- 20tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- 200tons per day

- 300tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- Middle type

- Large scale

- What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- 200tons per day

- 300tons per day

- Others