Automatic potato starch production line

Date:

Date:

November 8, 2018

- WhatsApp:

- Tel:

- Phone:

- Email:

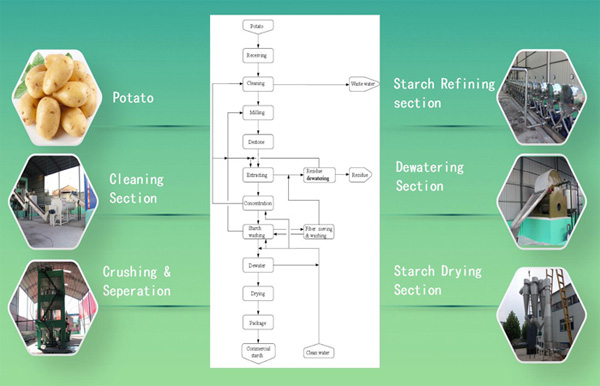

Potato starch extraction process is the most important process in potato starch production line. The starch grains contained in the potato cells are extracted by crushing the tubers, which releases them from the destroyed cells. The resulted starch is then washed out, dried to powder, and ready to use in either food or various technical applications.

Model of potato starch production line machines

Model of potato starch production line machines

Here is the introduction of potato starch production line production process:

Step 1- Sorting and weighing section: The roots are sorted to select wholesome roots for processing. The sorted roots are weighed.

Potato washing machine from Doing Company

Potato washing machine from Doing Company

Step 2- Potato cleaning and washing section in the potato starch production line : Using the Doing Company dry sieve and rotary washer which can fully cleaning and washing the potatoes.

Step 3- Potato crushing section: The cleaned potato will send into the rasper machine by the conveyor, then they will be crushed into a smooth mash. DOING rasper can fully crushing the potatoes, make a high starch extraction rate more than 94%.

Rasper machine for ginding the potato into powder

Rasper machine for ginding the potato into powder

Step 4- Potato starch extraction: The potato mash is discharged into the centrifuge sieve to remove the fibers to extract the starch, to guarantee the high quality potato starch produced from the potato starch production line, Doing Company will equipped the fine fiber sieve to further separation the starch slurry which aimed to remove the small fibers and small impurities. This is a key part for high quality potato starch production in the potato starch production line.

Step 5- Starch slurry washing and refinery process in potato starch production line: Now, hydrocyclone machine is an ideal machine for potato starch slurry refinery, it's a full sealing process, keep the liquid starch clean, after this processing section, we can get the starch milk(starch milk is clean and white, no impurities). Then the starch milk is allowed to send to the next step.

Centrifuge sieve

Centrifuge sieve

Step 6- Potato starch dewatering section: The vacuum filter used in the potato starch production line for the liquid starch dewatering process, DOING vacuum filter starch dewatering effect is good, water content of wet starch is stable, has realized automatic discharging, reduce the labor intensity. Compared with the old potato starch dewatering method, this automatic vacuum filter adopted in potato starch production line can improve the production speed, also improve and guarantee the finished potato starch quality.

Potato starch dewatering machine-vacuum filter

Potato starch dewatering machine-vacuum filter

Step 7 - Potato starch drying section: Doing Company flash dryer can rapidly drying the wet starch in potato starch production line, prevent the starch change to yellow, keep starch products white, high heat exchange rate, make sure the moisture uniformity. After drying, potato starch moisture will less than 18%, meet the first-class standard of potato starch.

Step 8 - Packaging: For your potato starch production line, Doing Company also supply the automatic starch packing machine for you.

Starch drying machine installated in potato starch production plant

Starch drying machine installated in potato starch production plant

In the last, it's worth to say that Doing Company offered automatic potato starch production line just need 4-5 people to operate, all the machines can be automatically controlled by special control cabinet, which is stable and not easy to damage.

Doing company recently have installed one potato starch production line project in ChongQing city in China, and the feedback is great. If you have any questions of potato starch production line machines, weclome to contact us, our engineer will give you a professional suggestions about the potato starch processing machine according to your requirement.

Leave a message about Automatic potato starch production line

- Do you want to buy machine?

- Yes, I want to buy machine

- No, I Just learning

- What is your raw material?

- Cassava

- Potato

- Sweet potato

- Others

- 2. What is the final product you want to produce?

- Garri

- Cassava flour

- Cassava starch

- Cassava chips

- Attiekie

- Bammy

- Others

- 3.What is your capacity plan?

- Small scale garri machine

- 1ton per day

- 2tons per day

- 3tons per day

- 10tons per day

- 20tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- 200tons per day

- 300tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- Middle type

- Large scale

- What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- 200tons per day

- 300tons per day

- Others