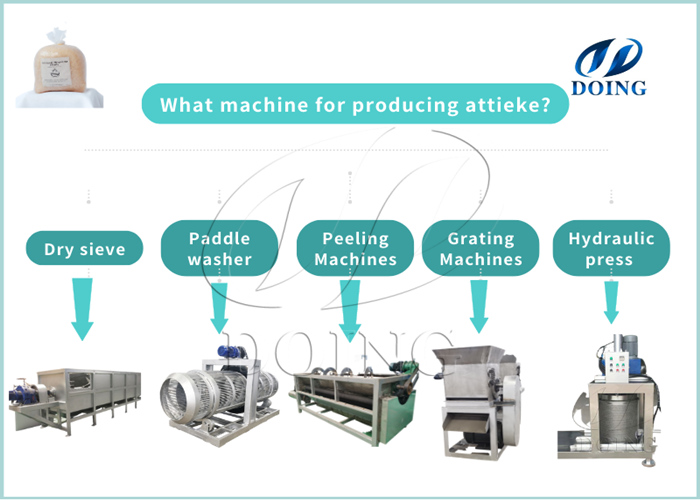

What machine for producing attieke?

Attieke is a popular food in many African countries, made from cassava. The traditional method of processing attieke involves manual labor, which is time-consuming and inefficient. However, with the advancement of technology, modern machines are now available to make the process faster and more efficient. In this article, we will discuss the machines needed for producing attieke.

In attieke producing, it will use washing machines, peeling machines, grating machines, dewatering machines, cooking machines, and packing machines.

What machine for producing attieke?

What machine for producing attieke?

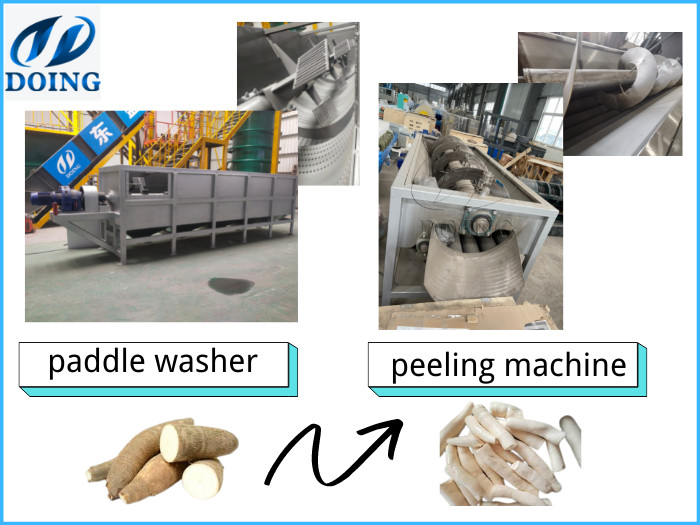

Washing Machines

The first step in attieke producing is washing the cassava. This is done to remove dirt, sand, and other impurities. Two types of washing machines are commonly used: the Dry sieve and the Paddle washer. The Dry sieve is used to remove large impurities like sand and leaves, while the Paddle washer is used to wash the cassava thoroughly.

Washing machine and peeling machine

Washing machine and peeling machine

Peeling Machines

After washing, the cassava needs to be peeled. Peeling machines are now available to make the process faster and more efficient in attieke producing. The peeling machines use a sand roller to peel the cassava.

Grating Machines

Grating Machines

Grating Machines

The next step of attieke producing is grating the cassava into a fine pulp. Grating machines are now available to make the process faster and more efficient. The grating machines use a rotating drum with sharp blades to grate the cassava into a fine pulp.

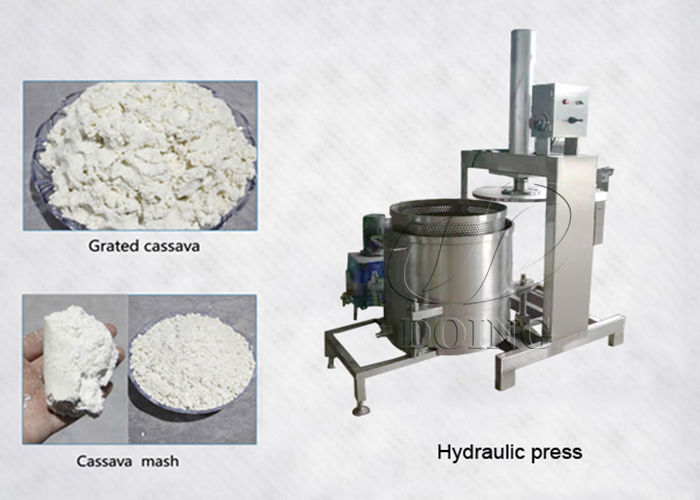

Dewatering Machines

Dewatering Machines

Dewatering Machines

After grating, the cassava pulp needs to be dewatered. This is done to remove excess water and make the pulp easier to cook. Hydraulic press machines are commonly used for dewatering in attieke producing. The dewatering machine use hydraulic pressure to squeeze the water out of the cassava pulp.

Cooking Machines

After dewatering, the cassava pulp is cooked by a steamer. Cooking machines and steamers are now available to make the process faster and more efficient.

Packaging machine

Packaging machine

Packaging Machines

The final step in attieke producing is the packaging. This is done to preserve the attieke and make it easier to transport. Packaging machines are now available to make the process faster and more efficient. The packing machine can package the attieke in various sizes and capacities.

Usually, attieke producing with low investment on the machine, so it’s a good business you can consider. If you want to start it, welcome to consult Henan Jinrui company.

Leave a message about What machine for producing attieke?

- Do you want to buy machine?

- Yes, I want to buy machine

- No, I want to learn more in advance.

- What is your raw material?

- Cassava

- Potato

- Sweet potato

- Others

- 2. What is the final product you want to produce?

- Garri

- Cassava flour

- Cassava starch

- Cassava chips

- Attiekie

- Bammy

- Others

- 3.What is your capacity plan?

- Small scale garri machine

- 1ton per day

- 2tons per day

- 3tons per day

- 10tons per day

- 20tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- 200tons per day

- 300tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- Middle type

- Large scale

- What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- 200tons per day

- 300tons per day

- Others