How to make fufu in Nigeria?

FUFU is a staple food in many countries(including Nigeria)and there is a large market to be developed. But there is a difference between the processing of fufu in small scale and large-scale industrial production.

If you want to make fufu by hand, you just need to wash, peel, cut, ferment, dehydrate, and then dry the cassava in the sun. It is suitable for homemade and mini fufu factories.

If you want to make fufu for sale, maybe you need to invest in industrial fufu production. There are three main sections: the cleaning section, the processing section, and the drying section.

Fufu washing machines

Fufu washing machines

Fufu Washing section

Fresh cassava is fed through a dry sieve to remove weeds and other foreign matter. Then sent to a paddle washer to wash off the sediment and stones. After that, the clean cassava is sent to the peeling machine to remove the inner and outer skins. This is the end of the cleaning section.

Fufu processing machines

Fufu processing machines

Fufu Processing section

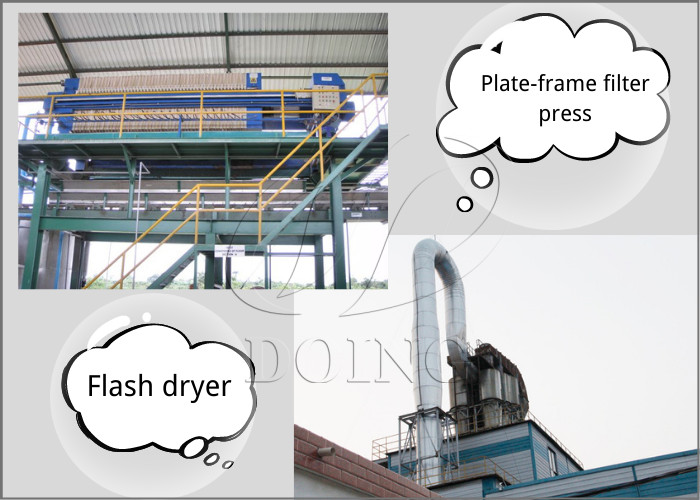

After peeling, the cassava is cut into small pieces by the cutting machine and then sent into the frustration mill to be beaten into fine cassava pulp. Next, it into the fermentation tank or ground pool for fermentation for about two days. This is the biggest difference from the traditional processing. Compared with fermentation after cutting, crushing into pulp and then fermentation can reduce the storage space and the difficulty of transporting to the next processing facility after fermentation. After fermentation, the cassava pulp is pumped into the plate frame for dewatering by a screw pump to complete the entire processing section.

Fufu drying machines

Fufu drying machines

Fufu Drying section

After dewatering, the FUFU is crushed into powder by the crusher and then sent into the two-stage airflow dryer by the hoist for drying, the humidity is reduced to below 14%, and the finished product is crushed twice by the fine crusher to ensure the quality of the finished product. The whole process of FUFU is completed.

If you want to get the fufu production line in Nigeria, you can go to our Nigeria branch to see the detailed equipment, and there will also be professional engineers to help you.

Leave a message about How to make fufu in Nigeria?

- Do you want to buy machine?

- Yes, I want to buy machine

- No, I want to learn more in advance.

- What is your raw material?

- Cassava

- Potato

- Sweet potato

- Others

- 2. What is the final product you want to produce?

- Garri

- Cassava flour

- Cassava starch

- Cassava chips

- Attiekie

- Bammy

- Others

- 3.What is your capacity plan?

- Small scale garri machine

- 1ton per day

- 2tons per day

- 3tons per day

- 10tons per day

- 20tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- 200tons per day

- 300tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- Middle type

- Large scale

- What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- 200tons per day

- 300tons per day

- Others