Process of making garri

Date:

Date:

June 18, 2019

- WhatsApp:

- Tel:

- Phone:

- Email:

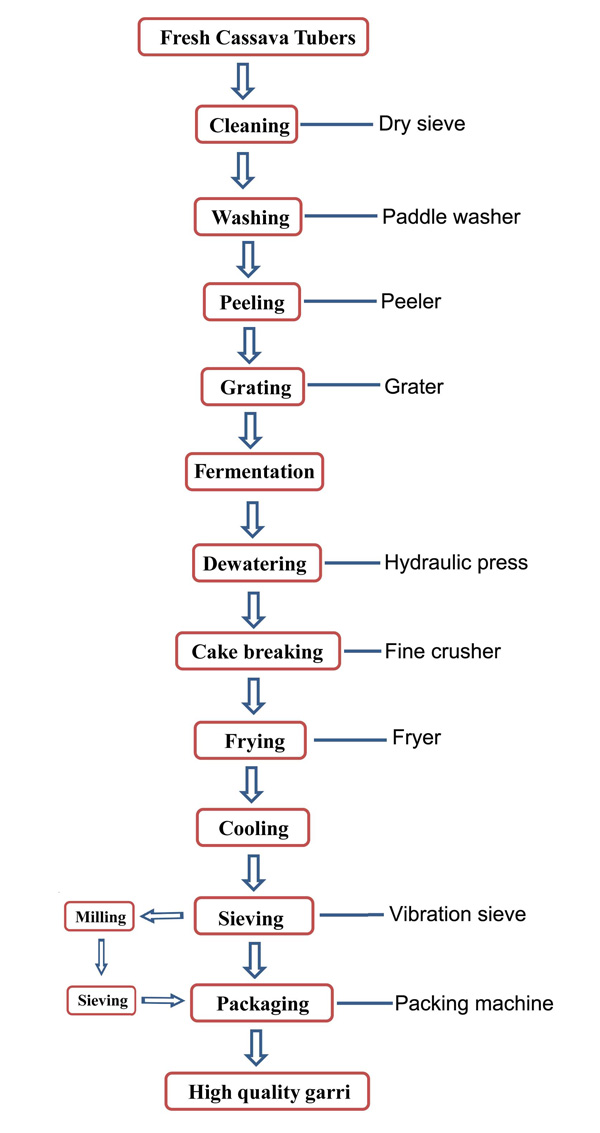

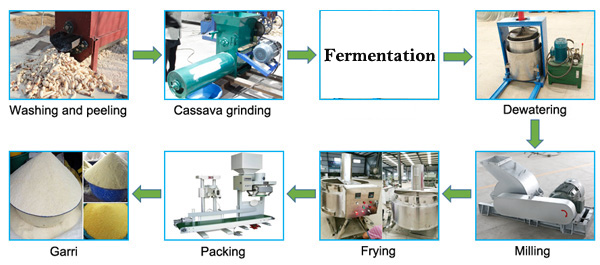

The process of making garri starts from cassava cleaning & washing, then go through peeling, grating, fermentation to garri dewatering and drying. With mechnical garri processing machine, the whole process can be finished within 30 minutes. Its capacity ranges from 10t/d to 100 t/d based on your budgets and requirements.

Here are the process of making garri:

1. To making garri, we need firstly to clean cassava by a dry sieve. Normally once clean can not remove all impurities, therefore a paddle washer is used in second process of making garri to get clean cassava.

2. Then we peel off the outer peels of cassava, and then grate it into mesh with a cassava grater.

High quality garri making process

High quality garri making process

3. Mill (or sifted) the cassava mash and then fried with or without palm oil.

4. Finally sieving the fried garri to get uniform fineness. The resulting dry granular garri can be stored for long periods. Get a popular daily food.

Although among processing steps also can made by manual, but to improve the processing speed and making high quality quality garri, making garri by automatic machines is essencial. The main garri making machine from Doing Company include cassava peeler(peel cassava tubers), grater(grating cassava tubers into mash), hydraulic press dewater(press to dewatering fermented mash), fryer(frying garri) and vibration sieve(sieving to get uniform fineness). If your production capacity is large, like one ton per hour, then you also need to add the professional cassava cleaning machines.

Garri making machines

Garri making machines

Processing of making garri into people's daily food:

Garri can be eaten without further cooking, as a snack, by placing it in a bowl and adding cold water; fineness garri very suitable for consumption in this way. Sugar or honey is then added as well as chunks of coconut, groundnuts, tigernuts and cashew nuts.

Leave a message about Process of making garri

- Do you want to buy machine?

- Yes, I want to buy machine

- No, I want to learn more in advance.

- What is your raw material?

- Cassava

- Potato

- Sweet potato

- Others

- 2. What is the final product you want to produce?

- Garri

- Cassava flour

- Cassava starch

- Cassava chips

- Attiekie

- Bammy

- Others

- 3.What is your capacity plan?

- Small scale garri machine

- 1ton per day

- 2tons per day

- 3tons per day

- 10tons per day

- 20tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- 200tons per day

- 300tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- Middle type

- Large scale

- What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- 200tons per day

- 300tons per day

- Others