The difference between a simple starch production line and an automated starch production line

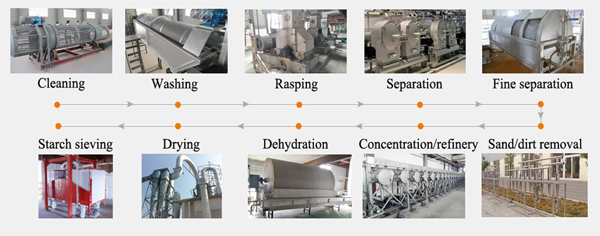

The production process of cassava, potato and sweet potato starch is basically the same, but the method of industrial starch production is simpler than simple manual production. The industrial automated starch production line is mainly composed of washing, grinding, sieving, separating protein, concentrated and refined starch slurry, dehydration and drying. The main difference between the traditional simple production method and the modern production method is that the automatic starch production line uses a centrifuge sieve or a hydrocyclone instead of the launder to separate impurities, and uses a peeler centrifuge or a vacuum filter for starch milk dehydration, professional starch dryer dries the starch, enabling starch processing to be automated and continuous for larger scale production and high yields.

Manpower starch processing

Manpower starch processing

The following is a brief introduction to the simple starch production line and automated starch production line:

First, the production of simple potato starch

1. Washing and grinding: The washing process of cassava, potato and sweet potato is done by a professional washing machine, and some simple production lines with small processing volume are also manually cleaned. In the cleaning stage, impurities such as mud, stones, stems and leaves, and muddy sand adhering to the surface of the potato are removed. The water consumption is about 2-3 times that of the raw materials. After washing, it is sent to the rasper for treatment and crushing. After the starch slurry is obtained, Doing's crusher can fully break the raw materials, so that the starch is fully released, and the starch extraction rate is over 94%.

2. Separation: The ground starch slurry is sieved. The traditional method is to use a flat shaker, a cylinder, etc. (Modern automatic starch plant uses centrifugal sieve to remove fiber and other impurities.) In the separation process, starch slurry needs to be washed with water. After sieving, it can get clean starch milk. The starch residue can be used as feed or brewing cassava wine.

Main starch production process and machines

Main starch production process and machines

3. Sedimentation or launder separation: The starch milk from the separation section is first precipitated in a sedimentation tank or a trough, the crude starch is taken out, and then the coarse starch is reprecipitated or rinsed.

4. Dehydration and drying: After the starch is cleaned, the water content is very high. The filter bag can be used for lifting and filtering, and the water inside can be filtered out, and then dried by manual drying or drying in a drying room and a dryer. It can also be used for direct processing fans and other starch products.

Second, automated cassava, potato, sweet potato starch production line:

The automated potato starch production process is basically similar to the simple production process. The main differences are as follows:

Modern starch processing plant overview

Modern starch processing plant overview

1. The cleaning stage is a little more. Sometimes the larger starch factory uses the launder to transport or clean the material, and the raw material is initially cleaned, and then thoroughly cleaned by the machine.

2. The separation device of the milled starch slurry uses a centrifugal sieve to separate the residue. And the crushing and separation are generally carried out continuously, with a short interval between them.

3. Use a disc separator or hydrocyclone to replace the launder or sedimentation tank to separate the protein: the separated and refined starch concentration can reach 20 Baume, then dehydrate and dry to obtain dry starch.

4. There are equipment(conveyors) connections between the various processes of the entire production line, continuous automated production process, reducing manual operations.

When the user chooses the starch processing equipment, if the budget is not sufficient or the market reason, the machine can be purchased according to the simple production line, but the factory room should have development in the equipment layout, so that the equipment can be increased and improved later, to improve the processing efficiency and product quality.

Finally, you can click cassava starch production machine to get more informations.