How to dry starch ?

Starch can be divided into different kinds such as potato starch, cassava starch, sweet potato starch and corn starch. In the process of starch production, the step of how to dry starch is very necessary and significant. And in the step, flash dryer can be applied. Usually, after dewatering starch, then the next step is drying section. After drying, then the starch will be sieved and packed.

Compared with the natural drying, adopt the professional starch drying machine can guarantee the starch quality high, whitness, clean, drying fast and evenly. And DOING flash dryer is a professional machine used for starch drying.

DOING starch dryer

The following part will explain how to dry starch by flash dryer. Flash Dryer is the ideal equipment for starch production. Starch dried by this equipment has features of clean appearance, glossy luster, smooth powder, and stable moisture while wheat gluten features in high water absorption, excellent activity and original flavor. Flash dryer can be designed and produced based on customers' requests on space and warehouse, which is convenient for installation, operation and maintenance. In the process of how to dry starch, air speed in this flash dryer is continuously changed because of different section diameters of pulse tubes, therefore, heating transfer coefficient is high and mass materials can be dried well. Flash dryer is especially designed for starch production, which could ensure complete dryness and product refining.

Flasher dryer installed in customer plant

Characteristics of flash drying system in the step of how to dry starch:

Using air instant drying principle, with the characteristics of high drying intensity.

2. Short drying time, low steam consumption and fast dewatering

3. High thermal efficiency and excellent quality of tapioca starch production;

4. High drying intensity and strong dewatering ability;

5. Simple structure, small area occupied and low investment

6. Negative pressure environment, clean and no pollution.

7. Mature technology application in tapioca starch production.

Heating for starch drying

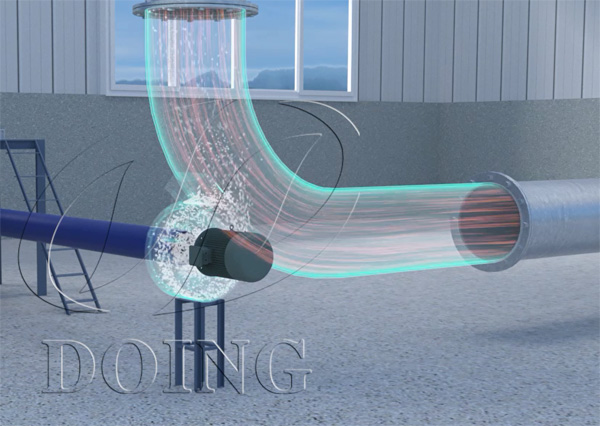

The working principle of flash dryer:

Sludge, powder and granular material are in the state of suspension under the effect of high-speed hot air in this process of how to dry starch. As flow speed is high, the wet starch particles suspended in air, the heat transfer surface and heat transfer coefficient of gas-solid is high, and drying time is short (most of the dry material less than 2 seconds), it is particularly suitable for drying of heat sensitive materials.

Hot air enters the stirring, crushing and drying chamber in a certain speed from the air inlet that at the bottom of dryer and produces vigorous eddy airflow. About how to dry starch, material is acted by centrifugal force, shearing force, impact and friction, the particle size of material becomes very small and mass and heat transmission is strengthened. At the bottom of dryer, big damp granules is crushed, small and low moisture content granules rise with the rotating air stream. During the rising process, the granules are dried further. Because of the rotary flow of air and solid, inertia of solid phase is higher than gaseous phase, the relative speed of air and solid is big, it strengthens mass and heat transmission, so drying intensity is high. This is the working principle of how to dry starch.

Leave a message about How to dry starch ?

- Do you want to buy machine?

- Yes, I want to buy machine

- No, I Just learning

- What is your raw material?

- Cassava

- Potato

- Sweet potato

- Others

- 2. What is the final product you want to produce?

- Garri

- Cassava flour

- Cassava starch

- Cassava chips

- Attiekie

- Bammy

- Others

- 3.What is your capacity plan?

- Small scale garri machine

- 1ton per day

- 2tons per day

- 3tons per day

- 10tons per day

- 20tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- 200tons per day

- 300tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- Middle type

- Large scale

- What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- 200tons per day

- 300tons per day

- Others