How to produce cassava flour?

Cassava flour is a very important ingredient in profitable production of bread. In 2001 Nigerian president was a farmer so had a first hand knowledge of what problems farmers were facing and the fact that Nigerian government was spending huge amount of money on wheat which is used to produce bread and some other confectioneries. The government directed Federal Institute of Industrial Research to find ways of including local raw materials in the production of bread. The outcome of the research is that cassava flour can be mixed with wheat at up to 10% without any adverse effect on the taste and texture of the product. The federal government then mandated all the flour mill to include cassava flour in their product since then, produce cassava flour has been a good profit project, cassava flour also more and more important in people diet.

So, how to produce cassava flour? There Doing Company will offer the answer:

Harvest matured cassava from the farm and load it to the processing shed immediately. If the quantity of cassava harvested can not be carried in the same day for logistic reasons do not detach the cassava from the stem and leaf until the vehicle to carry it is ready. That is to say, fermentation will not occur if the cassava is still attached to the leaf and stem even if it has been uprooted. But care must be taken not to bruise the cassava when uprooting it.

Step 2: Cleaning and washing cassava

Adopt our dry sieve+paddle washer can fully separate the cassava from impurities in the process of how to produce cassava flour. And in the cassava cleaning and washing process, some outter skin of cassava will be removed. Sufficient washing can guarantee the taste of cassava flour.

Step 3: Grinding and rasping

The tuber is grinded and become low broken percentage . That means 50% cassava flour is not separated and combined with fiber. In the rasping process, should add process water to dilute slurry. the cassava slurry in the collection trough is pumped in to desanding cyclone. So the special design of rasper is vital for cassava flour fineness and freeness, adopt rasper for cassava crushing process for how to produce cassava flour can get higher crushing effect, make your cassava flour tast better, more fineness.

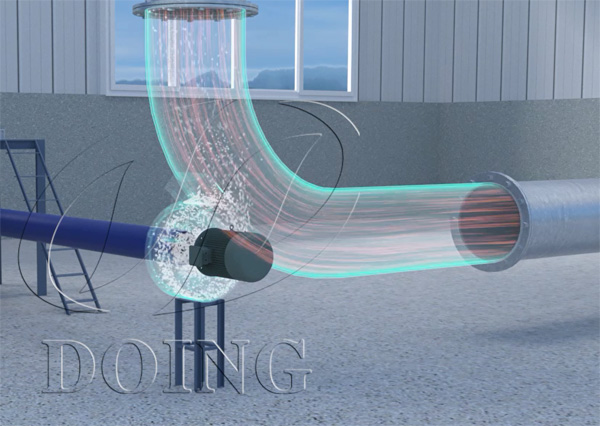

Step 4: Desanding

In the desanding process, sands and sawtooth etc coarse particle will be removed from cassava slurry. This unit is made of ceramic cyclongnetts, sands collection tank, automatic desanding valve and back flush device. Back flush avoid cassava flour loss in desanding process. Desanded slurry will sent to dewatering unit in the process of how to produce cassava flour.

Step 5: Dewatering

Because there is hydrocyanic acid toxic substance in cassava peels. In this unit, we use plate frame filter press to dewatering and detoxification process of how to produce cassava flour.

When slurry reaches to certain liquid position in slurry tank, start to dewater by filter presser. Then transport the material to cassava flour drying procedure by belt conveyor.

Step 6: Drying

Dewatered cassava flour cake contains high moisture to 45~50%, which can’t enter into flash dryer directly and will be mixed with dry flour and reduce the moisture to 38%, then transported to feeding port of flash dryer by conveyer belt, through feeder and enter into raiser.

The heat source of our cassava flour drying machine is steam heat exchanger. Wet cassava flour is heated by hot wind and water is steamed. After drying for how to produce cassava flour, cassava flour and air are separated in cyclone separator. At the bottom of cyclone separator, it is closed by air closer, after wet air leave cyclone separator, which is discharged in to atmosphere. Collected cassava flour is transported to vibration sieve unit; the coarse particulate matter is sieved out. The sieved cassava flour is transported to hopper for storing and cooling.

Step 7: Automatic Packing

1. Automatic weighing and calculating 2. Large adjustable weighing scope from 5-50kg 3. Hand seal, Packing cassava flour in different bags.

All in all, this is the complete process for how to produce cassava flour.

PREV:How many ways for cassava flour drying ?

NEXT:What can we do with the byproducts during cassava processing?

Leave a message about How to produce cassava flour?

- Do you want to buy machine?

- Yes, I want to buy machine

- No, I Just learning

- What is your raw material?

- Cassava

- Potato

- Sweet potato

- Others

- 2. What is the final product you want to produce?

- Garri

- Cassava flour

- Cassava starch

- Cassava chips

- Attiekie

- Bammy

- Others

- 3.What is your capacity plan?

- Small scale garri machine

- 1ton per day

- 2tons per day

- 3tons per day

- 10tons per day

- 20tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- 200tons per day

- 300tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- Middle type

- Large scale

- What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- 200tons per day

- 300tons per day

- Others